Apeks CO2 cannabis oil extractors for cannabis oil concentrate.

Award-winning cannabis and hemp extractions.

Designed by staff engineers with expertise in industrial automation and 17-plus years’ experience building cannabis oil extractors. Apeks Supercritical CO2 extraction systems efficiently extract pure, high-quality essential oils. While any botanical material can be extracted, the majority of our customers use Apeks equipment to extract oils from cannabis and hemp to produce CBD and other products.

Our customers are producing some award-winning oils with Apeks systems which feature simple fractional extraction and cold separation processes to preserve volatile oils for higher-quality and higher-quantity yields. When plant matter is exposed to too much heat or cold, terpenes (scent) and flavonoids (taste) are impaired (thermal degradation). We take every precaution to avoid this, which is why our systems are water jacketed.

High output Apeks Duplex® System – optimized for low pressure/low temperature subcritical extractions

Download a price list today!

Cannabis oil concentrate (Hemp)

Apeks machines are designed to extract cannabis oil concentrate. The new Duplex® system pulls oils very quickly in a subcritical extraction, which means less post processing work needs to be done because not many undesirable materials were extracted (fats, waxes, etc.). The Duplex® also allows for quick processing during supercritical run, if you’re wanting the entire extract. The quality of the cannabis oil depends on what you put in. If you put high quality cannabis in, for example with a 20% THC content, you’ll get 20% THC in return, but it will be concentrated. The base material is important – you can’t expect to put poor quality material in and get high quality oil out.

Controlled decarboxylation and greater yields of THCA.

TCHa is converted to THC via a chemical process using heat called decarboxylation. Apeks thermally-sensitive extraction equipment allow processors greater control over the decarboxylation of their extractions because cold separation does not decarboxylate (or very minimally) the extracted oils in the separator as most competitor systems do. Therefore, processors can produce on average a 20% greater yield of THCa. This is important because converting THCa to THC by decarboxylation activates the psychotropic elements of cannabis which some processors and end-users don’t want. Some prefer non-psychotropic cannabis concentrates to put in medical cannabis products aimed at children, or for patients who want the medicinal benefits, not the intoxicating effects.

Old Faithful - Hemp and cannabis extraction equipment.

Apeks systems have rightfully gained the reputation among processors and extraction experts as being solid performers, built to last. Knowing they’ll be working with their machines for many years, customers are known to affectionately call them by name like Old Faithful, The Workhorse and The Beast.

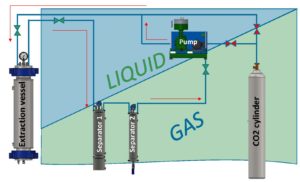

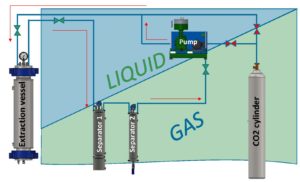

The systems work best with ground up, dried cannabis (or other) plant material. The plant material should be dried thoroughly. CO2 extraction doesn’t like water in the source material so drying the cannabis properly beforehand is essential. Customers in humid climates sometimes use freeze dryers to remove water from the plant. Once dried, the material should be ground to coffee-ground consistency before loading into the extraction vessel. CO2 is pumped through it, extracting the oil. The CO2 and oil move to the separator vessel where the denser, heavier oil drops down into a collection cup. The CO2 then continues its loop and is recovered in the gas canisters.

A winterization class in progress at our Johnstown, Ohio facility.

How to use cannabis or hemp extraction equipment.

Once the system is installed, customers will complete a ticket and training will be scheduled with one of our service engineers. They will come to your facility and train you on site. They will explain and show you how the machine works, and how to set up parameters for a variety of extractions. At the end of the half-day training, your operators should be comfortable running terpene runs, subcritical runs, and supercritical runs. We have a fully-staffed service department so if you run into problems, we’ll be happy to help. We also offer service plans so your system will continue extracting, year-round!

In addition to onsite training from one of our service engineers, we offer quarterly winterization classes at our Johnstown, OH facility. Winterization is the process to remove fats, waxes and lipids from the extract. Classes are a two-hour or four-hour block of training, and are free to existing customers, and $500 for non-customers. Customers who purchase from us within six months will get a full refund. The four-hour block of training includes an overview of short path distillation extraction equipment, which is a more intensive distillation process after winterization.

Techniques for cbd extraction machines.

Designed by staff engineers with expertise in industrial automation and 17-plus years’ experience building cannabis extraction equipment, Apeks Supercritical CO2 extraction systems efficiently extract pure, high-quality essential oils. While any botanical material can be extracted, the majority of our customers use Apeks systems to extract oils from cannabis and hemp to produce CBD and other products.

We have affiliates who will come to your location and teach you how to use your pre- and post-processing equipment. Depending on your set up, this could take 2-4 days and does incur an additional charge. The affiliates are not employees of ours, but offer this service to our customers.

We also offer a full complement of instructional videos on our YouTube channel, so you can figure out the best technique to extract your cannabis or hemp!

Complete a form to download a price list!

Download a price list today!

How to grind material properly

This video shows the grinding process:

Difference between subcritical and supercritical.

Apeks systems process either under subcritical parameters or supercritical parameters. Subcritical runs (low pressure/low temperature) extract flavonoids and terpenes, while supercritical (high pressure/high temperature) runs pull everything out of the plant including waxes and lipids. Many Apeks customers do one short terpene, subcritical run first, then finish the subcritical run before doing a supercritical run to get the most out of the plant matter as possible.

The lighter, terpene-rich oil on the left from a subcritical extraction, the heavier supercritical extraction on the right.

Watch the video to see a demonstration on the winterization process.

Selecting the right system for your industry needs.

We help customers and companies alike choose the appropriate Apeks system to purchase based on their processing capacity. Our sales team members ask, “What do you want to achieve?” and then work from there. A customer might be looking to produce high-grade concentrated oil for vape pens. In which case, we will advise them on terpene runs at subcritical parameters because they will be able to use the oil directly out of the machine without any need for post-processing. For those interested in high production subcritical extractions, check out the Apeks Duplex® designed to do just that.

During supercritical runs, the equipment will extract additional unwanted materials like fats, waxes, and lipids, which requires the oil undergo post-processing after extraction. Customers should consider whether they need to do post-processing, referred to as winterization, or if they can use the oil straight out of the machine.

This is our introductory system, and processes 10-14lbs of dried botanical material per day.

As companies grow, they’ll move up to The Transformer. There are five different configurations and can process 25-31lbs per day.

At this point you’re looking at high production since this system has a very high flow rate (6.1kg/min) and can process 126-180lbs per day!

This system is the largest and strongest of our systems and can process 140-200lbs per day.

This is not a system, but a platform that allows you to daisy chain up to three Duplex or Force systems, giving you the capacity of 600lbs per day.

During supercritical runs, the system will extract additional unwanted materials like fats, waxes, and lipids, which requires the oil undergo post-processing after extraction.

Other information about Apeks systems.

Apeks Supercritical CO2 extraction systems are all manufactured to the highest industry standard, in our ASME-certified facility. System control panels are UL listed meeting the nationally recognized standards for safety. Additionally, we offer peer review documents in multiple states. Our extraction equipment comes with a 3-year warranty, which is longer than many of our competitors have been in business!

Comprehensive training and support are included in the purchase. One of our service engineers will travel to a new customer’s facility to teach how to perform terpene, subcritical, and supercritical runs on their Apeks system. In addition, we have several engineers and a full customer support staff available to troubleshoot and resolve issues online. Since our systems are fully automated, customers don’t have to hire a machine operator to run extractions. Once parameters are set, and the start button is engaged, they can attend to other matters.

Watch how easy it is to start one of our systems.

Properly maintained, our equipment will only need major service every 4,000 hours. We recommend a thorough cleaning between runs. This helps extend the life of the seals and other parts.

Apeks systems are constructed in a 17,000-square-foot purpose-built manufacturing facility in Johnstown, OH. The company is veteran owned and operated. Veterans receive a 5% discount on purchases.

A leader in the extraction industry, Apeks Supercritical is nationally recognized for manufacturing innovative, quality, warranty-backed systems built by experienced engineers. Read more about the Apeks Advantage and our unique equipment features and capabilities that other industry manufacturers do not offer.

Download a price list today!

COntact Us

Got questions? We have answers.

For more information about our Apeks Supercritical systems please fill out the contact form below and we will respond to you shortly.