Apeks Supercritical’s oil extracting machine.

Fully automated, closed-loop CO2 botanical oil extraction systems.

Fractional or short path distillation

Extractions produce higher yields when the plant material is completely dry. Some Apeks customers (especially those who live in humid climates) use a freeze dryer to remove all the moisture. Once totally dried, the plant matter is ground to the consistency of coffee grounds.

Here’s a video about grinding plant material:

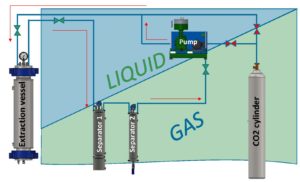

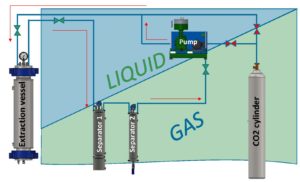

To begin an extraction run, place the ground-up plant material into the system’s extraction vessel which must be sealed properly. The fully automated system prompts the machine operator via the touchscreen user-interface to verify parameter settings based on the type of extraction preferred. Once the parameters are set, the system is ready to start.

A short extraction run (about 20 minutes) at subcritical parameters (low pressure, low temperature), known as a terpene run, extracts light oils, full of terpenes, the plant’s aromatic compounds. These terpene-rich extracts are ideal for vape pens. Longer subcritical and supercritical runs (high pressure, high temperature) extract more of the plant material. In addition to the lighter oils, supercritical CO2extracts the higher molecular weight materials (waxes, paraffins, lipids and resins) allowing for higher yields. However, these extractions require post processing to remove the fatty substances from the oil (see winterization).

Winterization

Winterization is the process of removing undesirable plant material (waxes, etc.) from the “crude” oil after a supercritical extraction. To winterize, 200-proof alcohol is added to the extract, mixed well, and placed in a deep freezer overnight. The next day, the mixture is filtered into a funnel where the fatty substances are trapped on filter paper. This can be repeated several times. Once all the fats and waxes are removed, the alcohol is removed by gently heating the oil using a rotary evaporator. Alcohol boils at a different temperature than oil, so it boils off, leaving pure essential oil behind.

Watch a winterization video here:

Short Path Distillation

Oil can be even further refined by short path distillation, which separates different compounds within the oil. For example, if coconut oil without the coconut scent is desired, compounds containing the scent can be distilled off. Similarly, cannabis-specific compounds can be selected, some of which are used in very targeted medicines. Each compound has a different boiling point so by heating the oil, each compound can be siphoned off as it reaches its particular boiling point.

Read more about short path distillation here.

Clearer doesn't necessarily mean better.

While clear oils remain popular, the additional processing to further refine them by removing waxes and unwanted substances also strips away many of the beneficial minor compounds found in cannabis. For example, a clear THC oil does not offer the full spectrum of terpenes and other therapeutic compounds. One of our customers, Dr. Markus Roggen from Outco Oil, has written about this and what’s known as “the entourage effect.” Read the article here.

Award-winning cannabis and hemp extractions.

Apeks offers different sized, expandable oil extraction machines to meet the needs of small, medium and large-scale operations. The Introductory model extracts 7-10 pounds per day, Mid-Range models up to 30 pounds/day, and High Production models up to 100 pounds/day. The High Production Duplex system, optimized for high-speed subcritical extractions, produces pure oils requiring no post processing and extracts 20 minutes per pound. Prices of Apeks systems range from the low $80,000’s to the mid-$400,000’s.

High output Apeks Duplex™ System – optimized for low pressure/low temperature subcritical extractions

The Apeks Advantage

All systems are designed, fabricated and built on site at the Apeks purpose-built manufacturing facility in Johnstown, OH. Conversely, some other manufacturers purchase parts from a number of different sources, which not only reduces the reliability of their machines but also makes customer support extremely difficult. At Apeks, the customer support staff, in consultation with the on-site engineering team, is available by phone, email and online.

The Apeks online parts store is always fully stocked. Parts can be sent for overnight delivery, to minimize any downtime. Full system maintenance is required only every 4,000 hours; however, regular cleaning between runs is recommended for optimal performance. Apeks offers full maintenance service (although customers can do it themselves) for $6,000 to $15,000, depending on the size of the system.

Download a price list today!

COntact Us

Got questions? We have answers.

For more information about our Apeks Supercritical systems please fill out the contact form below and we will respond to you shortly.